Shaft encoders are responsible for converting the positioning angle of a shaft within a digital code. With the help of a shaft encoder, devices can perform precisely. Shaft encoders usually operate within a motion control system. Shaft encoder is a common type of feedback sensor in various mechanical applications. They typically reduce excessive movement, which can cause the mechanical equipment to malfunction. An absolute shaft encoder is a necessity for industrial equipment as it can withstand shock and vibration.

Shaft Encoders Are Easy To Install

The installation process of a shaft encoder is more convenient and less time consuming than other motion restrictors. A shaft encoder is easily adjustable, which implies that you can fit it just above the motor. Unlike different types of encoders which should match the exact size of the motor, hollow shaft encoders are flexible. Moreover, shaft encoders save you money as you can use this device for more than one application.

Shaft Encoders Offer Moderate Resistance

Another highlighting trait of a shaft encoder is that it offers moderate resistance against shock. If you work within an industry which needs you to lift heavy products, you need something durable and affordable. This is where shaft encoders come to the fore. Shaft encoders feature a force-resistant design which enables them to resist impacts from heavy equipment. They are also suitable for various industries as they are easily adaptable with a variety of types of machinery.

Shaft Encoders Exude Simplicity

When compared to other devices, shaft encoders can be mounted directly to a motor. This helps in the prevention of excessive rotation. It also helps curb vibration. Shaft encoders comprise of flexible torque arms which ensures overall stability. A shaft encoder is simple yet effective and is ideal for a plethora of industries operating across various domains. It can also contribute to the logic system of a particular equipment and provides data regarding the shaft’s rotation.

Facilitates Accuracy Even In Complex Systems

A shaft encoder quickly determines the position using a static reference point. A shaft encoder is intrinsically able to deliver higher quality feedback in the following ways.

- Accurate motion detection along multiple axes

- Better recovery in case of power or system failures

- Provides better startup performance of the device because of low homing time

- Higher overall resolution and orientation

- Various output protocols for better electronics integration

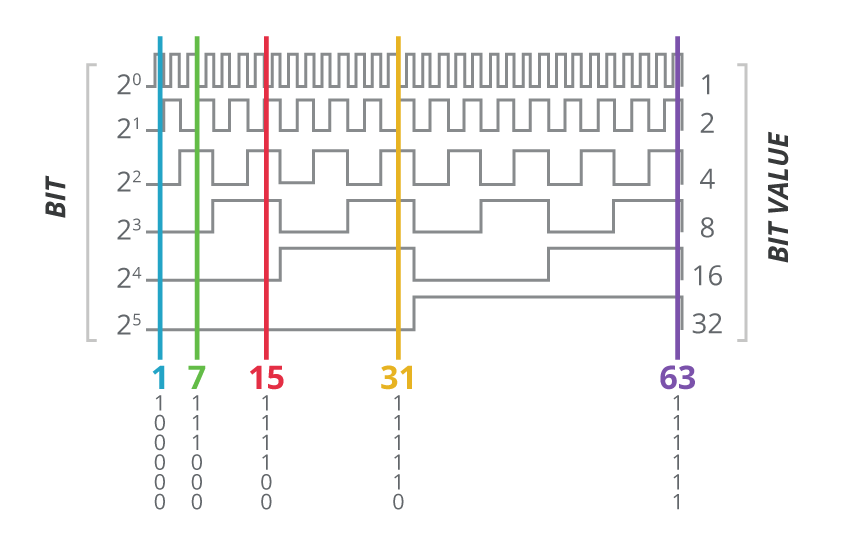

Shaft encoders are available with different output options. Shaft encoders use binary coding effectively.

Situations Where You Need Shaft Encoders

Shaft encoders enable applications which rely on non-linear positioning to work without additional external components.

- Automatically determining the height of scissor beds used in hospitals

- Accurately positioning multiple stabilizers for large vehicles like cranes or aerial lifts

- Moving automatic doors or bays without a limiting switch

- Continuing robotic movement cleanly even after a power failure

Shaft encoders have a definite edge over resolvers and incremental encoders. They have a higher positioning accuracy, which affects the overall application performance in an industrial setting.